Precision Grinding Services

No. 1 Precision Grinding Company in New Haven, MI

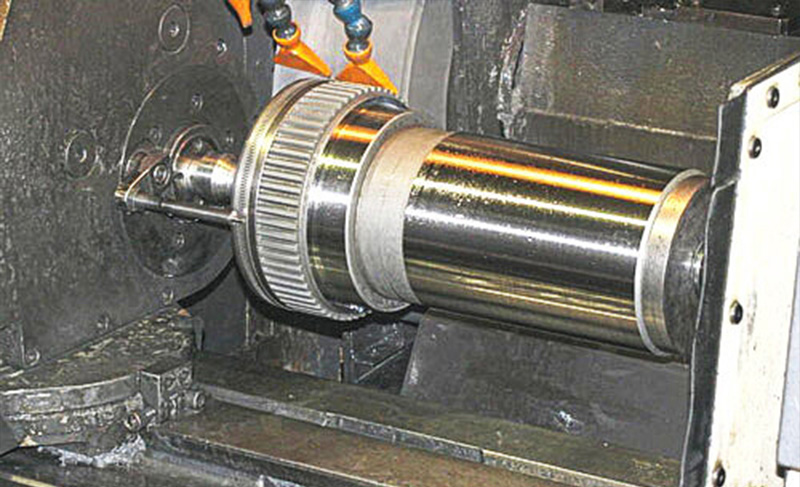

Sturdy Grinding is the most reliable precision grinding company in New Haven, delivering high-quality surface finishes and meeting tight tolerances for various industries. Our advanced grinding machines, including surface grinding and centerless grinding, can handle metal parts of all sizes, from long bars to complex workpieces.

We use abrasive wheels to achieve precise surface finishes, ensuring a workpiece's surface meets exact specifications. With expertise in various types of grinding, such as OD grinding and creep feed grinding, we offer unmatched precision for both ferrous metals and non-ferrous materials. Contact us today to experience why Sturdy Grinding is the trusted choice for industries needing reliable, high-quality grinding solutions in New Haven, MI.

Our Metal Grinding Services

- Centerless End Feed/Plunge Grinding: This process uses a centerless grinder to achieve precision grinding on the ends of metal parts, perfect for creating smooth surfaces on smaller, high-volume components. The grinding wheel rotates to remove material efficiently, ensuring tight tolerances in a variety of applications.

- Centerless Thru-Feed Grinding: Ideal for high-volume production, centerless thru-feed grinding allows continuous feeding of long bars or tubes through the grinder, achieving uniform finishes. This precision grinding process is excellent for parts requiring consistent diameters and smooth surface finishes.

- Bar Stock Grinding: Bar stock grinding is used to grind long bars to meet precise dimensions, making it ideal for industries requiring straight and round components. This process delivers high-quality finishes, ensuring the bar stock maintains its integrity for further manufacturing.

- CNC OD Grinding: CNC OD grinding uses computer-controlled machines to perform precision grinding on the outer diameter of metal parts. This process is ideal for complex shapes or parts that demand tight tolerances, delivering consistent results even in high-volume projects.

- I.D. Honing: I.D. honing refines the inner diameter of a workpiece, creating smooth, accurate finishes ideal for cylinders, tubes, or parts requiring a precise internal surface. This process is excellent for achieving tight tolerances and improving the quality of holes in metal components.

Precision Grinding Services Diverse Industries, Including:

- Aerospace: Precision grinding for stainless steel shafting, titanium shafting, titanium tubes, linear shafting, aluminum bars, and aluminum tubes to meet stringent quality requirements.

- Automotive: Grinding services for axle shafts, armature shafts, planetary gears, assorted transmission parts, intermediate shafts, and bearing journals (cam-shafts) to ensure high accuracy and efficiency.

- Defense: Expertise in grinding machine gun tripods, M4 & M16 bolt carrier groups, large caliber naval shells, missile and torpedo shells, and prototype equipment across a wide range of materials like steel, aluminum, graphite, copper, bronze, brass, stainless steel, and titanium.

- Medical: High-grade grinding for microscope shafting, stainless steel shafting, and titanium shafting with exacting tolerances, providing smooth, blemish-free surfaces required for medical equipment.

- Oil Exploration: Precision grinding for beryllium copper tubes and bars, ensuring straightness and specific size and surface finish tolerances for critical oil exploration equipment.

Highly-Reviewed Griding Company

More TestimonialsPrecision Grinding Services FAQs

How Often Should I Inspect My CNC Grinding Machine?

You should inspect your CNC grinding machine daily for basic checks, such as lubrication levels, wear on grinding wheels, and overall cleanliness. A more detailed inspection should be done monthly, focusing on the machine's alignment, coolant levels, and moving parts to ensure optimal performance and prevent malfunctions.

What Are the Most Common CNC Machine Malfunctions?

The most common CNC machine malfunctions include spindle issues, tool breakage, misalignment, and software errors. These problems often arise from improper maintenance, incorrect machine settings, or wear and tear on parts like bearings, belts, and grinding wheels.

What Is Centerless Grinding?

Centerless grinding is a precision grinding process that uses a rotating grinding wheel and a stationary regulating wheel to remove material from the surface of a workpiece without the need for a central spindle. This method is ideal for producing smooth, accurate surfaces on cylindrical parts, especially in high-volume production.

How Has Centerless Grinding Impacted The Manufacturing Industry?

Centerless grinding has significantly impacted the manufacturing industry by providing a more efficient and precise way to produce cylindrical parts with tight tolerances. It enables high-volume production with consistent quality, reducing material waste and enhancing productivity across various industries, from automotive to aerospace.

What Is End Feed Grinding?

End feed grinding is a variation of centerless grinding where the workpiece is fed into the grinding machine from one end, allowing it to be ground on a specific portion. This technique is commonly used for producing complex shapes, tapers, or parts with multiple diameters, ensuring precision and high-quality finishes.

Not Convinced? See for Yourself at Our Portfolio Page

Our portfolio highlights a wide range of successful grinding projects, showcasing the precision and quality we deliver for various materials, including bar stock grinding and I.D. honing. Serving multiple unique industries, Sturdy Grinding demonstrates expertise in achieving optimal dimensions and surface finishes on the surface of a workpiece.

Explore our work today and contact us to see how we can meet your grinding needs with excellence and precision.